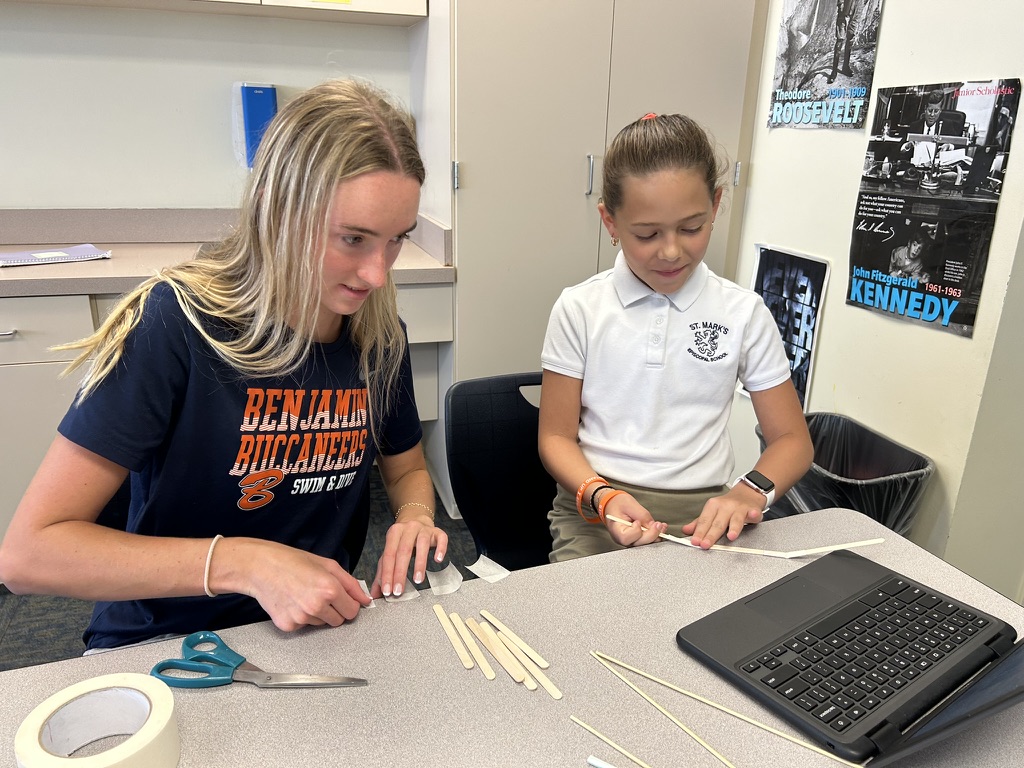

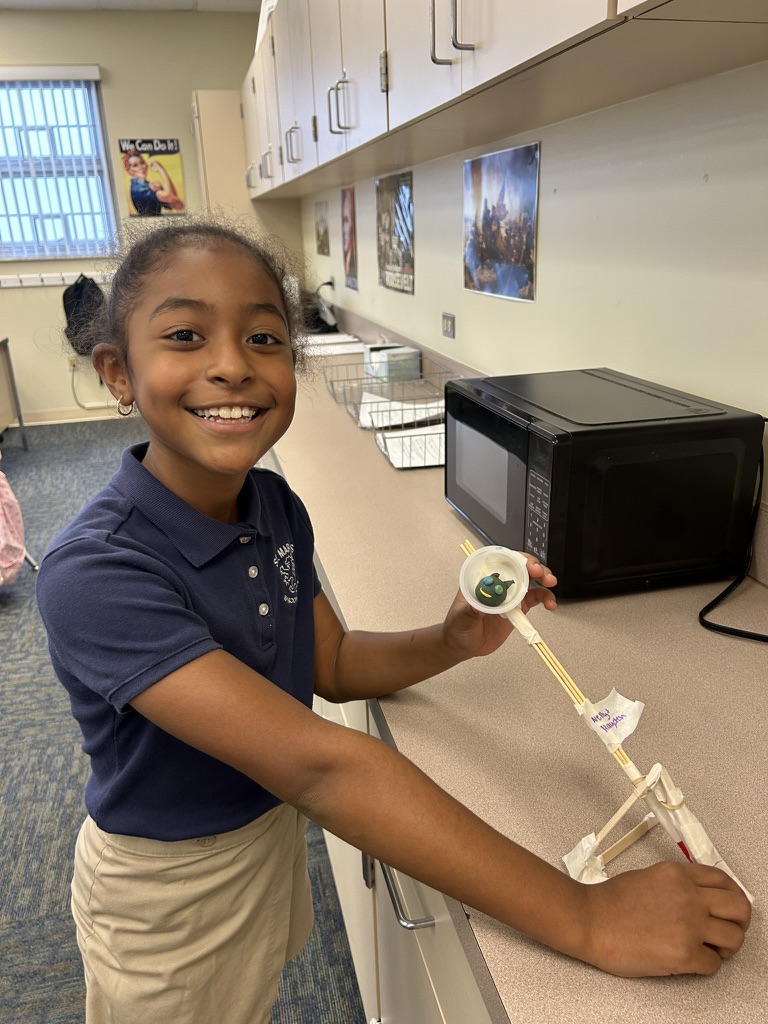

One of our most recent projects in Materials Girls was making catapults from wood, plastic, and tape. The amount of tape we used was absurd. It got me thinking: is there a more sustainable adhesive we could have used? There are so many complex materials in the world beyond what we know from the periodic table. While the elements themselves are fixed, the ways we combine and engineer them are nearly limitless. I recently discovered the material Galvorn, and it definitely has the potential both scientists and I are looking for.

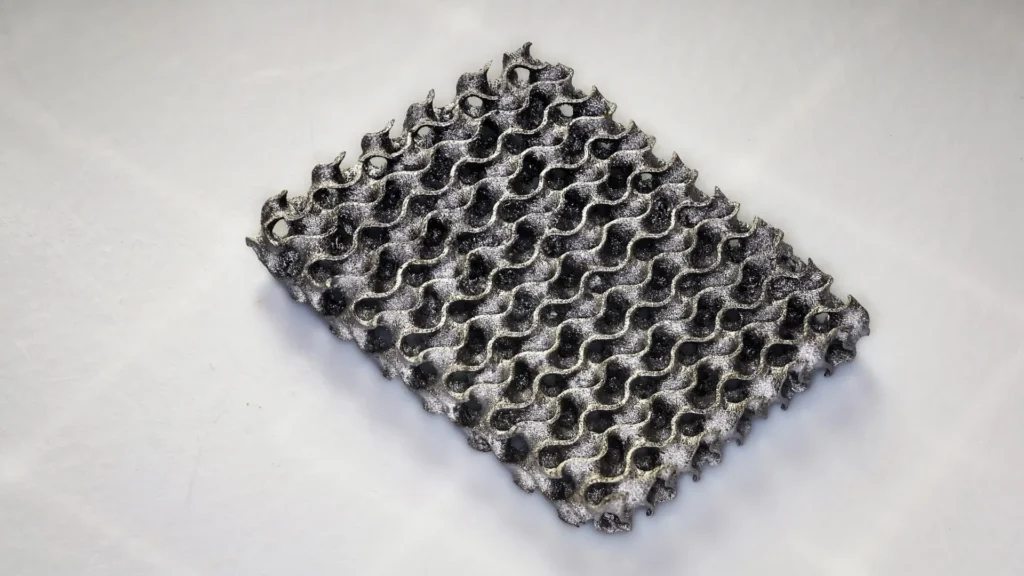

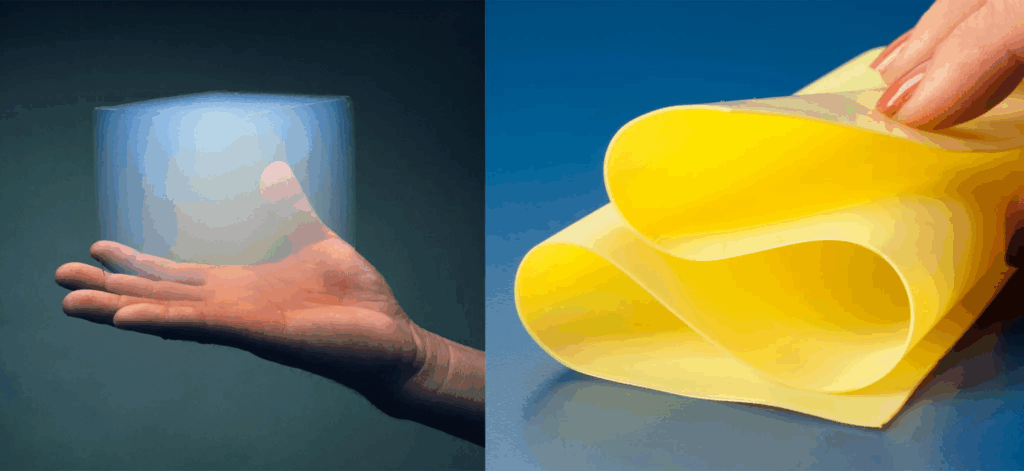

Scientists are buzzing about Galvorn, a new carbon-based material developed by Houston-based DexMat that is being hailed as “magical” for its extraordinary properties: it’s stronger than steel, lighter than aluminum, and as conductive as copper. Backed by over $20 million in funding from the U.S. Air Force, DOE, NASA, and other major agencies, Galvorn is produced through a high-tech carbon-splitting process and can be formed into tape, yarn, mesh, or thread. Inspired by the elven metal described in Tolkien’s The Silmarillion, the real-world version is designed to solve very human problems: reducing reliance on copper, cutting carbon emissions, and enabling cleaner manufacturing. Experts say its potential climate impact is “dizzying,” with applications ranging from lighter vehicles and wind turbine blades to stronger infrastructure, high-conductivity batteries, and even de-icing airplane wings. Because it is made from carbon and manufactured with electricity—often renewable—Galvorn can lock carbon away long-term while displacing heavier, more polluting materials. DexMat’s goal is nothing short of transforming global infrastructure as the world moves toward electrification, with some investors calling Galvorn one of the most impactful materials they’ve ever encountered.

Galvorn proves that the next era of technology may depend on creative engineering rather than rare, expensive metals. It’s still early, but if DexMat succeeds, this material could become a cornerstone of sustainable design for decades to come.

References

Kazmer, Rick. “Scientists discover ‘magical’ material that’s stronger than steel and lighter than aluminum — and its potential is dizzying.” Yahoo! Tech, 2 December 2025, https://tech.yahoo.com/science/articles/scientists-discover-magical-material-stronger-100000581.html.