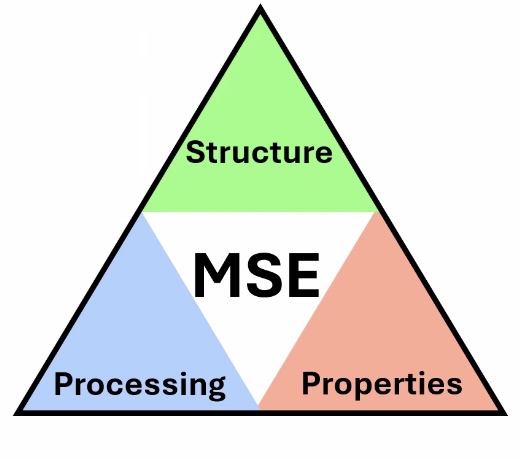

Two days ago I was on a Zoom call with a university about their Materials Science and Engineering department, and it made me rethink what I knew about the field. The woman associated with the school mentioned the MSE triangle and that any MSE class I will take will guarantee to mention this. I had heard of this triangle before but her discussion made me rethink what I knew about Materials Science and Engineering.

Structure, Processing, and Properties

MSE studies how structure, processing, and properties of materials are related. Structure describes how atoms and molecules are arranged, from the microscopic crystal lattice to larger grain patterns. It determines how strong, flexible, or conductive a material can be. Processing refers to the methods used to shape, treat, or manufacture materials such as heat-treating steel, casting metals, or 3D printing polymers. These processes directly influence the structure, whether by altering grain size, creating new phases, or aligning fibers. Finally, properties are the measurable characteristics we rely on (strength, toughness, conductivity, corrosion resistance) and they emerge from the interplay of structure and processing. The beauty of the triangle is that no corner exists in isolation. Change the processing, and you alter the structure; shift the structure, and you change the properties. This interconnected framework guides scientists and engineers in designing materials for everything.